Single-phase motors are widely used in household and industrial applications due to their simplicity and efficiency. They rely on a capacitor to initiate and maintain operation, ensuring optimal performance in various setups. These motors are cost-effective, versatile, and ideal for applications requiring minimal power consumption. Understanding their wiring is essential for safe and efficient installation.

1.1 Overview of Single-Phase Motors

Single-phase motors are AC motors designed to operate on a single-phase power supply, making them ideal for household and light industrial applications. They are simple, compact, and cost-effective, requiring minimal maintenance. These motors often use capacitors to create a phase shift, enabling them to start and run efficiently. Common types include capacitor-start and capacitor-run motors, each tailored for specific tasks. Their versatility and reliability make them a popular choice for fans, pumps, and small appliances. Understanding their operation and wiring is crucial for safe and efficient installation, ensuring optimal performance in various setups.

1.2 Importance of Capacitor-Start Motors

Capacitor-start motors are essential for applications requiring high starting torque and efficient operation. The capacitor creates a phase shift, enabling the motor to start reliably under load. This design ensures smooth operation, reduced vibration, and increased efficiency. Capacitor-start motors are ideal for heavy-duty tasks, such as compressors and pumps, where consistent performance is critical. Their ability to handle high starting currents makes them a preferred choice in industrial and household applications. The capacitor’s role in initiating and maintaining operation ensures optimal performance, making these motors highly reliable and versatile for various electrical systems.

Fundamental Principles of Motor Wiring

Motor wiring involves connecting components like windings, capacitors, and terminals to ensure proper current flow. Understanding phase shifts and capacitor functions is crucial for efficient operation and safety.

2;1 Basic Components of Single-Phase Motors

Single-phase motors consist of main and auxiliary windings, a centrifugal switch, and capacitors. The main winding is directly connected to the power supply, while the auxiliary winding, paired with a capacitor, provides the starting torque. The centrifugal switch ensures the auxiliary circuit disconnects once the motor reaches operating speed. Capacitors store electrical energy, enabling phase shifts necessary for motor rotation. Terminals are labeled for connections, with markings like “C” for common, “F” for fan, and “H” for compressor. Proper understanding of these components is essential for safe and efficient wiring, adhering to the motor’s nameplate specifications for voltage and connections.

2.2 Role of Capacitors in Motor Operation

Capacitors are essential for initiating and maintaining single-phase motor operation. They store electrical energy, creating a phase shift between the main and auxiliary windings. This phase shift generates the necessary starting torque. Starting capacitors provide a high voltage boost during startup, while running capacitors maintain efficient operation. The centrifugal switch disconnects the starting capacitor once the motor reaches speed. Proper capacitor selection based on motor specifications ensures optimal performance. Incorrect capacitor use can lead to poor starting, overheating, or motor failure. Always refer to the motor’s nameplate for capacitor ratings to ensure reliable and efficient operation.

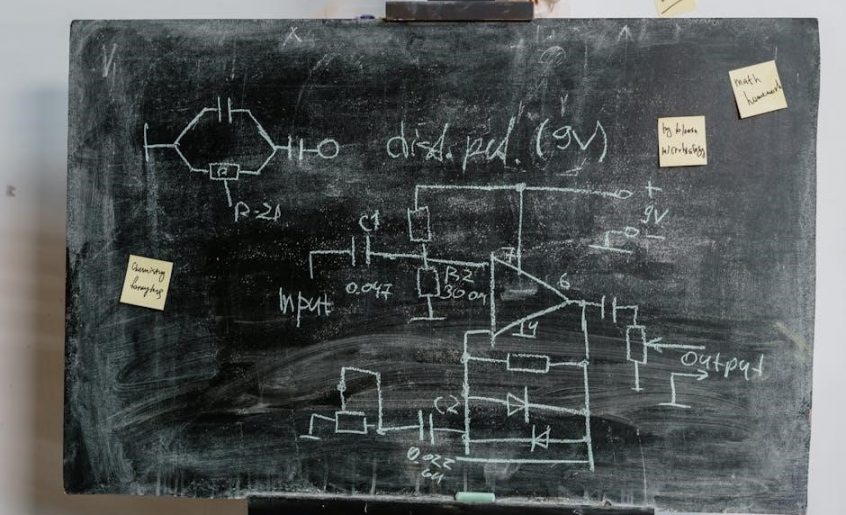

Understanding the Wiring Diagram

The wiring diagram provides a clear visual guide for connecting the motor, capacitor, and power supply. It shows terminals, windings, and capacitor connections, ensuring safe installation and operation.

3.1 Key Elements of the Wiring Diagram

The wiring diagram includes essential components such as the main and auxiliary windings, starting and running capacitors, and terminal connections. It illustrates the power supply lines, capacitor placement, and direction control for motor rotation. The diagram also highlights safety features like overload protection and proper grounding. By following the diagram, users can ensure correct wiring, preventing motor damage and ensuring efficient operation. Each symbol and connection is clearly labeled, making it easier to identify and connect components accurately. This visual guide is crucial for both installation and troubleshooting.

3.2 Terminal Markings and Connections

Terminal markings are crucial for correct wiring. Common terminals are labeled as C or COM, while the starting and running windings are marked S1 and S2. Capacitors are connected between C and S1 or S2, depending on the diagram. The main winding connects to the power supply lines L1 and L2. Directional control is achieved by reversing specific wires. Always refer to the motor’s terminal box for precise markings and ensure connections match the wiring diagram. Proper terminal connections prevent motor damage and ensure safe, efficient operation. Verify all connections before powering up the motor.

Essential Safety Considerations

Always disconnect power before wiring to prevent electrical shocks. Use protective gear like gloves and safety glasses. Ensure all components are rated for the motor’s voltage and current to avoid hazards. Follow the manufacturer’s guidelines and local electrical codes for a safe installation. Proper grounding is crucial to prevent accidents and ensure reliable operation.

4.1 Safety Precautions Before Wiring

Before starting the wiring process, ensure the power supply is completely disconnected to avoid electrical shocks. Wear protective gear, including insulated gloves and safety glasses, to prevent injuries; Verify that all components, such as capacitors and terminals, are compatible with the motor’s voltage and current ratings. Use a multimeter to check for any residual voltage in the circuit. Ensure the workspace is well-ventilated and free from flammable materials. Never attempt to wire a motor without proper training or guidance. Always refer to the manufacturer’s instructions and local electrical codes for compliance. Proper preparation and caution are critical to ensuring a safe and successful wiring process.

4.2 Protective Equipment and Tools

Essential protective equipment includes insulated gloves, safety glasses, and a multimeter to ensure safe handling of electrical components. A well-equipped toolkit with wire strippers, pliers, and screwdrivers is necessary for precise connections. Always use a voltage tester to confirm power disconnection. Protective gear prevents electrical shocks and injuries from sharp wires or tools. Proper tools ensure secure and accurate wiring, minimizing risks and ensuring reliability. Investing in quality equipment is crucial for both safety and successful motor installation.

Components Involved in Wiring

Key components include main and auxiliary windings, starting and running capacitors, centrifugal switches, and terminal connections. These elements ensure proper motor operation and efficient energy use.

5.1 Main and Auxiliary Windings

The main winding is responsible for generating the primary magnetic field, while the auxiliary winding creates the secondary field necessary for starting the motor. The main winding is typically larger to handle higher currents during operation. The auxiliary winding, connected to a capacitor, provides a phase shift to create a rotating magnetic field. Proper connection of these windings is crucial for the motor to start and run efficiently. The wiring diagram specifies the correct terminals for each winding, ensuring the capacitor is appropriately integrated for optimal performance and motor longevity.

5.2 Starting and Running Capacitors

Starting capacitors are designed to provide a high starting torque, enabling the motor to initiate operation efficiently. Running capacitors, on the other hand, are used to improve the motor’s efficiency and power factor during continuous operation. The starting capacitor is typically disconnected once the motor reaches its operating speed, while the running capacitor remains in the circuit. Proper selection and connection of these capacitors, as specified in the wiring diagram, are essential for optimal motor performance. The capacitors’ voltage and capacitance ratings must match the motor’s requirements to ensure reliable operation and prevent overheating or premature failure.

Step-by-Step Wiring Process

- Disconnect power supply for safety.

- Identify motor terminals using the wiring diagram;

- Connect the starting capacitor to the auxiliary winding.

- Link the running capacitor to the main winding.

- Ensure all connections are secure and test the motor.

6.1 Preparing the Motor and Components

Begin by ensuring the motor is disconnected from the power supply for safety; Identify the main and auxiliary windings using the wiring diagram. Inspect and discharge any capacitors to prevent electric shock. Verify the motor’s nameplate for voltage and horsepower specifications to select the appropriate capacitor. Gather necessary tools like wire strippers and pliers. Securely mount the capacitor near the motor to minimize wire length and reduce interference. Double-check all terminals and connections against the wiring diagram to ensure accuracy. Finally, test the motor to confirm smooth operation and proper function.

6.2 Connecting the Capacitor and Windings

Connect the capacitor to the auxiliary winding, ensuring one terminal links to the line supply and the other to the winding. The main winding is connected across the power lines. Refer to the wiring diagram to identify specific terminals. Ensure the capacitor is correctly rated for the motor’s voltage and horsepower. Double-check connections to avoid mismating. Secure all wires tightly to prevent loose connections. Power up the motor and test for smooth operation, verifying proper starting torque and efficiency. Always follow the diagram and safety guidelines to ensure a safe and reliable setup.

Troubleshooting Common Issues

Common issues include faulty capacitors, loose connections, and incorrect terminal links. Check for blown fuses, capacitor failures, and wiring mismatches. Ensure all connections are secure and correctly matched.

7.1 Identifying Faults in the Wiring

Identifying faults in the wiring of a single-phase motor with a capacitor start involves checking for common issues such as loose connections, incorrect terminal links, or damaged wires. Start by ensuring the power supply is disconnected for safety. Use a multimeter to verify continuity and resistance in the windings and capacitors. Look for signs of overheating, which may indicate a short circuit or overloaded motor. Check the capacitor for swelling or leakage, as these are signs of failure. Ensure all terminals are securely connected and match the wiring diagram. If the motor fails to start, verify the capacitor is properly sized and rated for the motor’s specifications. Consult the wiring diagram to trace connections and identify mismatches. Addressing these issues promptly prevents further damage and ensures reliable operation.

7.2 Resolving Capacitor-Related Problems

Resolving capacitor-related issues in single-phase motors involves checking the capacitor’s condition and connections. Ensure the capacitor is correctly rated and sized for the motor. Look for swelling or leakage, which indicates a faulty capacitor. Verify connections match the wiring diagram. Use a multimeter to test capacitance and wiring integrity. Address overloading issues to prevent capacitor stress. Consider other components like switches or windings if the capacitor isn’t the problem. Replace faulty capacitors with appropriately rated ones and ensure all connections are secure for reliable operation.

Downloadable PDF Resources

Access comprehensive guides, wiring diagrams, and troubleshooting tips in downloadable PDF formats. These resources provide detailed instructions for single-phase motor wiring with capacitor start configurations, ensuring safe and efficient setup.

8.1 Accessing Detailed Wiring Diagrams

Detailed wiring diagrams for single-phase motors with capacitor start configurations are readily available in downloadable PDF formats. These diagrams provide clear visual representations of motor windings, capacitor connections, and terminal markings. They include step-by-step instructions for installing and troubleshooting motors, ensuring safe and efficient wiring. The diagrams cover various motor types, including capacitor-start and capacitor-run configurations. Printable guides allow for easy reference during installations. Users can access these resources through official manufacturer websites, technical forums, or dedicated electrical engineering platforms. These PDFs are essential for professionals and DIYers alike, offering comprehensive guidance for proper motor setup and operation.

8.2 Printable Guides for Easy Reference

Printable guides offer a convenient way to reference wiring diagrams and instructions for single-phase motors with capacitor start configurations. These guides are designed to be user-friendly, providing clear, organized content that can be easily accessed on-site or in the workshop. Many guides include troubleshooting tips, step-by-step wiring procedures, and detailed diagrams to ensure accurate installations. They are often compatible with mobile devices, allowing professionals and DIYers to consult them on the go. Printable resources also help reduce errors by providing a quick reference for capacitor sizing, terminal connections, and safety protocols. Their portability and clarity make them indispensable for efficient motor wiring projects.

Advanced Topics in Motor Wiring

Explore advanced techniques like variable frequency drives for speed control and motor protection circuits to optimize performance and prevent overloads in single-phase motor systems.

9.1 Speed Control and Variable Frequency Drives

Variable frequency drives (VFDs) offer precise speed control for single-phase motors by adjusting the input frequency and voltage. This advanced technology enhances efficiency and reduces wear, allowing motors to operate at varying speeds smoothly. VFDs are particularly useful in applications requiring adjustable torque and power, such as fans and pumps. By integrating a VFD with a capacitor-start motor, users can achieve dynamic performance while maintaining the motor’s reliability. Proper wiring and configuration are crucial to ensure optimal functionality and energy savings.

9.2 Motor Protection and Overload Prevention

Protecting single-phase motors from overloads and electrical faults is crucial for longevity and safety. Circuit breakers, thermal overload relays, and fuses are commonly used to prevent damage from overcurrent. Proper capacitor sizing ensures stable operation, while voltage regulators maintain consistent power supply. Overload prevention involves monitoring motor current and temperature, ensuring it stays within rated limits. Regular maintenance, such as checking wiring and capacitor condition, further enhances reliability. By implementing these protective measures, motor efficiency is maximized, and the risk of premature failure is significantly reduced, ensuring safe and efficient operation in various applications.

Single-phase motors with capacitor start offer efficient and reliable operation for various applications. Proper wiring ensures safety, performance, and longevity, making them a practical choice for everyday use.

10.1 Summary of Key Points

Single-phase motors with capacitor start are essential for various applications, requiring proper wiring for efficiency and safety. The motor comprises main and auxiliary windings, with the capacitor initiating operation. Understanding the wiring diagram is crucial, as it guides connections between components like terminals and capacitors. Safety precautions, such as disconnecting power before wiring, are vital. Correct capacitor sizing, as specified by the motor’s nameplate, ensures optimal performance. Troubleshooting involves checking capacitors and wiring, while direction control may require terminal adjustments. Following these steps ensures smooth motor operation and longevity.

10.2 Final Tips for Safe and Efficient Wiring

Always refer to the motor’s wiring diagram and nameplate for specifications. Ensure power is off before starting any work. Use the correct capacitor size and type to avoid motor damage. Double-check connections for accuracy, and verify polarity to prevent issues. Regularly inspect wiring and components for wear or damage. Keep all protective equipment on hand and follow safety guidelines. Proper grounding is essential for safety and performance. Test the motor at low voltage initially to ensure correct operation. Following these steps ensures a safe, efficient, and reliable wiring process for your single-phase motor with a capacitor start.